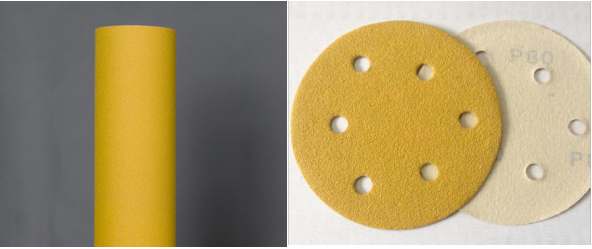

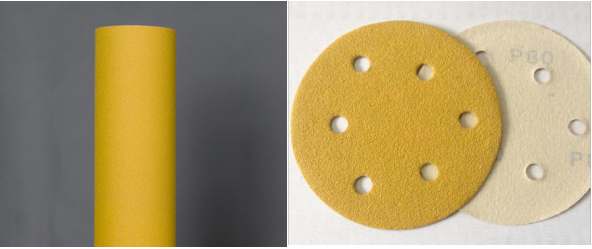

Dry abrasive paper uses synthetic resin as binder to bond silicon carbide abrasives on latex, and coating with anti-static coating to make high-grade products. It has the advantages of anti blocking, anti-static, good flexibility and high wear resistance. A variety of fineness options, suitable for grinding metal surfaces, putty and coating. The dry sanding paper is generally made of special kraft paper and latex paper, natural and synthetic resin as binder, and is manufactured by advanced high electrostatic sand planting process. This product has high grinding efficiency and is not easy to stick chips. It is suitable for dry grinding. Widely used in furniture, decoration and other industries, especially rough grinding.

Character:

1、 Using soft and elastic base materials, the product has good flexibility and can process a more smooth surface;

2、It is made of specially treated European standard abrasives, advanced alumina abrasives with good grinding force and durability, with higher grinding efficiency and good surface finish and consistency;

3、The use of high temperature resistant resin and high-strength base material can give full play to the durability of the product;

4、 Special surface anti blocking coating can avoid abrasive blocking and maximize the performance of sandpaper;

5、 It is suitable for dry and wet grinding.

Application:

1、Primer grinding and paint surface grinding, such as ship's intermediate painting and primer grinding.

2、grinding of synthetic materials, such as burring sharp edges and surface adjustment after plastic products are formed.

3、 Grinding of metal and aluminum alloy to remove foreign matters and surface particles.

4、 It is suitable for making all kinds of brushed and self-adhesive rubber discs.

Normal size:

Standard size:Circle 5 Inch、6 Inch Nap piece

Roll:1.15 m×100m/roll;Others can be customized.

Mesh:P800—P60

Application:

|

|

|

|

Lacquer surface grinding

|

Metal grinding

|

Furniture grinding

|